CONTACTLESS MEASUREMENT

The electromagnetic-acoustic thickness gauge allows user to measure the thickness of metal products with one-way access without using couplant through a substantial gap (up to 6 mm). This significantly reduces the material- and laboriousness of the measurement process.

MEASUREMENT THROUGH PAINTED, OXIDIZED OR OILY SURFACES

EMA technology generates waves directly in the material (ferromagnetic and paramagnetic), thus allowing measurements to be carried out under a coating or with a poorly prepared surface, which may not be feasible with traditional methods.

HIGH TEMPERATURE PROBES

EMAT Thickness Gauge NOVOTEST UT-3M-EMA can be equipped with probes for operation on surfaces heated to a temperature of 600 °C, which makes this device the best, and in some cases, the only possible solution.

MEASUREMENT RANGE

A significant advantage over competitors is the range of measured thicknesses. The EMAT Thickness Gauge NOVOTEST UT-3M-EMA allows measuring walls from 0.5 mm to more than 200 mm, depending on the probe used.

THICKNESS GAUGE EXECUTION

EMAT Thickness Gauge NOVOTEST UT-3M-EMA is made in a durable and lightweight metal case. By special order, the thickness gauge can be made in dust and waterproof design (IP65). The thickness gauge is equipped with lithium-ion high-capacity batteries, which allowed for a long battery life. By special order, the battery capacity can be further increased, which will allow user to operate up to 30 hours from a single battery charge.

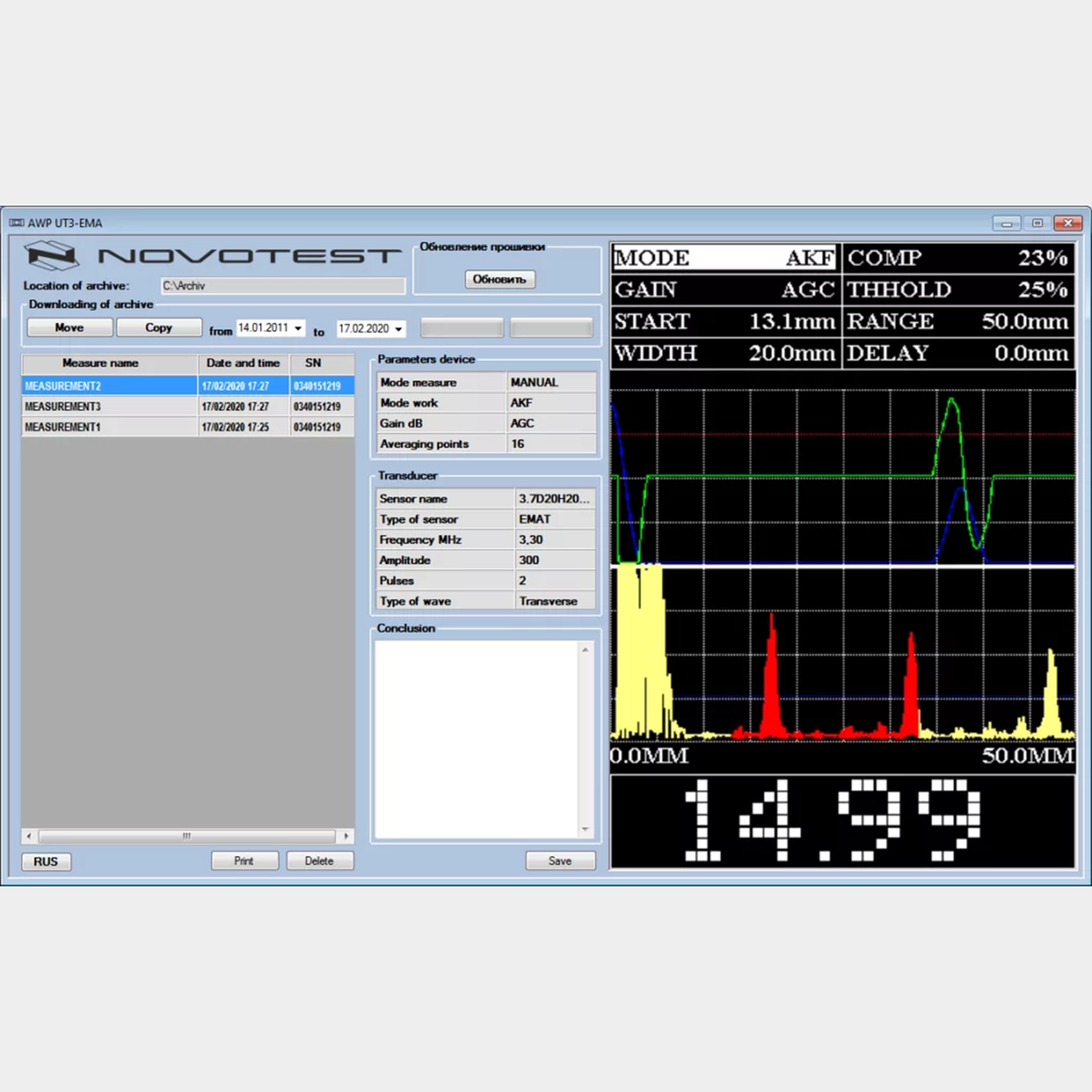

AUTOMATIC OPERATION MODE AND VARIOUS TYPES OF SIGNAL DISPLAYING

The EMAT Thickness Gauge NOVOTEST UT-3M-EMA implements a unique operating mode – the device automatically analyzes the measured signals, selects the required measurement method, adjusts the parameters of the receiving path and displays the measured thickness on the device’s screen. Even an unskilled user with this mode will be able to accurately and rapidly measure the thickness of various metal structures and products.

By default, the signal in the device is displayed like an A-scan, and the available operating modes allow the operator to evaluate the signals using different methods (PEAK-PEAK, FRONT, ECHO, ECHO-ECHO). Also the B-scan mode is implemented in this thickness gauge, which allows user to get the product profile like a graphical, convenient for perception. Using a specialized carriage for the probes, it becomes possible to scan extended objects and obtain a thickness profile. Also, EMAT Thickness Gauge NOVOTEST UT-3M-EMA comes with special software for operate with the archive of the device, and the subsequent transfer of data for processing in convenient formats.

.png)